Heat Exchangers - Find new uses for your heat plant. | |

For many installers, trying to cram multiple heat plants in a mechanical room is a daunting task. Many others have many heat plants to choose from. We have never had so many choices before. Condensing and Non-Condensing boilers, Water Heaters, Wood/Waste Oil/Bio-Fuel Boilers, Solar, Geothermal, etc. We also have many ways of using that heat; space heating through radiant floor/walls/ceilings or fin-tube radiators, fan-coils, domestic hot water, snow melting, pool/spa heating, green houses, etc. How does an installer incorporate these many heat sources with the various demands the building may have without mixing the water systems? "Wait! Why can't we mix water systems?" you ask. Well, each source/demand may have water chemistry issues. Some may need anti-freeze like solar, wood boilers and snow melting. Others may need to be highly controlled like domestic hot water. So the best way to exchange heat without mixing fluids is to use a heat exchanger. |

|

| Heat exchangers come in many shapes and sizes. The most commonly used for residential applications are flat plate heat exchangers. These are built with corrugated plates, usually stainless steel, stacked to create passage ways between the plates, then brazed or bolted together to create two flow paths through the heat exchanger. One path for the supply fluid and one for the demand fluid. But the two fluids never mix and the heat is transferred through the plates. These flat plate heat exchangers are usually quite small with excellent heat transfer characteristics. Another type of heat exchanger is the Shell and Tube heat exchanger. Shell and tube heat exchangers are constructed with a shell type vessel with a smaller tube type coil immersed inside the shell. These heat exchangers are used when higher flow rates are required. |  |

Flat Plate Heat Exchangers |

|

Examples of Heat Exchanger Uses:

|

|

Shell and Tube Heat Exchanger |

|

|

|

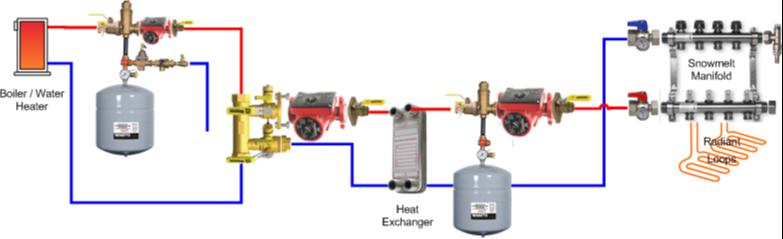

Typical Snow melting Heat Exchanger Piping Diagram |

|

When piping up a heat exchanger the installer should always use a "Primary/Secondary" piping configuration. There should always be a primary pump on the boiler to make sure there is sufficient flow through the boiler. Then use a separate secondary pump to control flow through the supply side of the heat exchanger. Using this two pump primary/secondary technique you will be able to regulate flow through the boiler with any number of secondary zones taking heat out of the primary loop. It will also ensure boiler life and performance. Also note that air elimination and expansion tanks are needed for both sides of the heat exchanger in closed systems. Add to your system, a sufficient control system to regulate flow and temperature and you have a great way of getting additional duty out of your heat plant. The controls will be very specific to the demand you are supplying so make sure you consult us for requirements and options. Visit our website at Pexheat.com to view our lines of heat exchangers or Contact Us at Pexheat.com for sizing and options. |

|

Pexheat.com, Brian Whitehurst

September 24, 2021

Tags

Archive

Sign in to leave a comment