One of the most popular ways of getting radiant floor heating into a home.

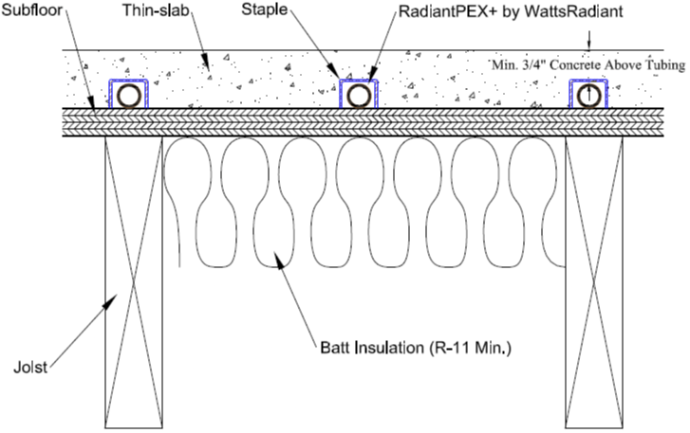

If you have an existing slab without tubing, you can pour a new thin slab with tubing over the existing slab. One of the most popular methods of installing hydronic floor heating in homes today is to pour a thin concrete slab over an existing subfloor and put radiant floor tubing in the thin slab.

The thin concrete slabs with allow for maximum heat transfer at minimum water temperatures which increased thermal efficiency and comfort. They also allow for rapid changes in floor temperature due to their lower heat mass such that the occupants can lower the room temperatures when the room is not in use and recover quickly when occupied.

Thin slabs are also easy to install. Installers staple the tubing to insulation over the existing slab or subfloor and then masons pour the slab over top of the tubing. With labor costs being some of the highest expense, an easy to install floor can be a cost savings. The slabs can be as thin as 1-1/2 in. to inhibit cracking, but can be thicker due to the needs of the flooring system.

The tubing will usually be installed on tighter spacing (8 in. on center) in thinner slabs to maintain uniform floor temperature. Thicker slabs will use large spacings (12 in. on center).

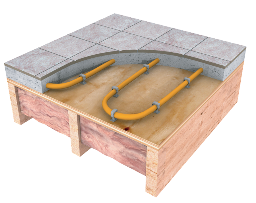

Thin Slab Over Subfloor

Tubing stapled to to subfloor with a thin light concrete slab poured over tubing.

Concrete Slab Overpour

Pour a new thin slab over an existing slab. Used mostly n basements.

Thin Slab Over Steel Decking

Commercial buildings and some homes have steel decking as a subfloor where a concrete slab is poured to create the floor. By all means put tubing in it.

The thin slabs can be made from:

- Concrete - Gravel and sand with a Portland cement binder. Relatively inexpensive, hardness and strength can be increased with additives.

- Gyp-crete - Gypsum and sand with a Portland cement binder. Lighter than Concrete but softer. Usually finished with a floor covering such as tile or floating wood floor.

Some of the drawbacks of thin slabs:

- Weight - If you are installing the thin slab over a subfloor system you need to consider the extra weight the floor system will have to support.

- Height - Thin slabs will add a minimum of 1-1/2 in. to the flooring height which needs to accounted for in door, window, cabinetry, etc.

- Moisture - The concrete will add a significant amount of moisture to the building. If there is not a means of dealing with the moisture there can be additional issues.

- Cost - Although thin slabs are installed quickly with minimum labor costs, they are usually expensive per square foot in material cost.

Types of Thin Slab Tubing

Hydronic slab heating tubing comes in a few different choices and some find it quite confusing. Here is a little details on tubing materials.

PEX

One of the most popular tubing materials for slab heating. Low cost, high flexibility, very durable and up to 25 year replacement warranties.

PERT

The next generation of plastic slab heating tubing. More flexible than PEX, lower cost, durable and 25 year warranties available.

PEX-AL-PEX

Has been around for a long time. There is a layer of PEX on the inside of the tubing for corrosion resistance. Surrounded by a layer of aluminum for strength and oxygen barrier. Then a layer of PEX on the outside of the tubing for durability. This is nice tubing to install since the aluminum maintains the tubing shape. I.e. if you bend the tubing it will stay bent. If you straighten the tubing it will stay straight. It does not expand with temperature as PEX and PERT tubing's do.

EPDM

The most flexible tubing we have on the market. The most durable tubing we have on the market, almost unable to be damaged. 25 year warranties available however the most expensive tubing. But if you price out a system you may find the EPDM tubing the best for your application. We have seen snow melting slabs installed in close to freezing temperatures with textured slab cuts greatly benefit from the flexibility of the EPDM tubing.

Manifolds

Distribution of heating fluid to the multiple loops used in the slab. Manifolds take the most abuse of any component in a Slab Heating System. Choose your manifold wisely.