5) PEX A, B and C is a grading system

Some think that the PEX-a, PEX-b and PEX-c designations are a grading system or description of performance for PEX tubing. Actually the designation is for the manufacturing processes which have been developed over the years.

Some think that the PEX-a, PEX-b and PEX-c designations are a grading system or description of performance for PEX tubing. Actually the designation is for the manufacturing processes which have been developed over the years.

PEX-a - The earliest method of cross-linking PEX tubing was the Peroxide Method also know as the Engel Process developed in Europe in the 1960s. "This method employs organic peroxides that, when heated, generate reactive free radicals that splice PE chains together during extrusion. This is sometimes referred to as the PEX-a Process." - Plastics Pipe Institute (PPI)

PEX-b - The Silane method is one of the most widely used methods for the manufacturing of PEX tubing. "This method involves grafting a reactive silane molecule to the backbone of the polyethylene. This is sometimes referred to as the PEX-b Process." - PPI

PEX-c - The electron beam method for cross-linking PEX tubing and often called the "clean" method because no peroxides are used. "This method involves subjecting the extruded PE pipe to a dose of high-energy electrons. This is sometimes referred to as the PEX-c Process." - PPI

Each method has it's benefits and it's detractions such as; PEX-a is marketed as the most flexible PEX available but this flexibility comes at a loss of chlorine resistance and lower burst pressures. PEX-b has the highest chorine resistance and burst pressures but at a loss of flexibility. PEX-c proponents cite it's clean composition but it does stand out as being more durable or having high chlorine resistance.

For more info see: PPI PEX Design Guide, DESIGN GUIDE - RESIDENTIAL PEX WATER SUPPLY PLUMBING SYSTEMS

4) Higher Cross-Linking makes a better tubing

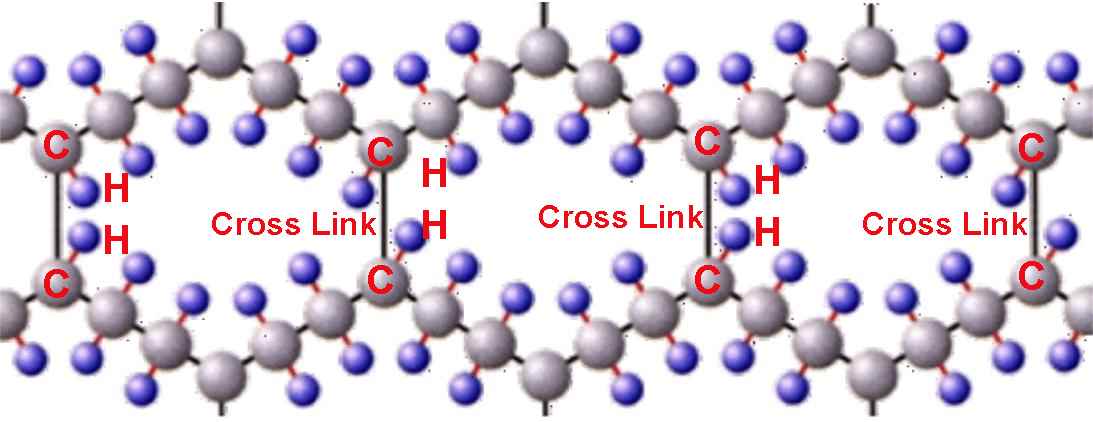

Cross-linking is the stabilizing of the High Density Polyethylene (HDPE) polymer into a material that will not break down. HDPE is clean and cheap and it can also be recycled, that is why it is such a good material for drinking water bottles. However, it breaks down pretty quickly and is not very good as a building material. Cross-linking the HDPE will allow it to handle higher temperatures, give it more chemical resistance and inhibit cracking. So higher Cross-linking is better right? Not so much.

Cross-linking is the stabilizing of the High Density Polyethylene (HDPE) polymer into a material that will not break down. HDPE is clean and cheap and it can also be recycled, that is why it is such a good material for drinking water bottles. However, it breaks down pretty quickly and is not very good as a building material. Cross-linking the HDPE will allow it to handle higher temperatures, give it more chemical resistance and inhibit cracking. So higher Cross-linking is better right? Not so much.As the HPDE is cross-linked the manufacturer has to either add "free radicals", or create the siloxane bridge. The manufacturer adds enough "free radicals" such that when they are used up the tubing should reach the desired cross-linked level, or as in the PEX-b method the cross-linking takes place for some time after the tubing has left the extruder. It is almost impossible to get a completely cross-linked tubing. Also the tubing becomes more brittle as cross-linking increases.

Manufacturers balance the level of cross-linking to the performance characteristics desired. Therefore, do not buy on cross-linking amounts as it is not a measure of performance.

http://plasticpipe.org/pdf/tn-17_crosslinked_polyethylene_pex.pdf

- Concrete Slab - Use a tubing with a higher burst pressure for greater durability.

- Thin slab or sleeper system - Use a tubing with greater flexibility.

- Municipal water - Use a tubing with a higher chlorine resistance.

- Under floor installation (Staple Up) - Use a PEX tubing a low friction layer or aluminum core (PAP) to minimize noise.

3) 5/8 in. tubing is better than 1/2 in. tubing.

First of all; is the tubing listed by outer diameter (OD) or inner diameter (ID). The industry standard is to list tubing by it's Nominal ID. However, some manufactures list their products by outer diameter. So make sure you are comparing the same size tubing. SDR-9 is a PEX tubing sizing system. So if you are selecting a fitting or tubing make sure it is an SDR-9 compliant size.

Second - what is the application? To minimize cost we always want to chose the smallest diameter tubing for the application. If we are carrying hot or cold water from one point to another usually our only concern is to be able to deliver sufficient volume and pressure for the use at the other end of the pipe. So if you need more flow or more pressure, yes a large diameter tubing will help. However, if our use is for heat transfer we have more to consider.

PEX Tubing Size Information | |||||

Nominal ID | OD | Wall Thickness | Avg. ID | Bend Radius | Volume gal/100' |

3/8" | 0.500 | 0.070 | 0.350 | 4" | 0.500 |

1/2" | 0.625 | 0.070 | 0.475 | 5" | 0.921 |

5/8" | 0.750 | 0.088 | 0.574 | 6" | 1.34 |

3/4" | 0.875 | 0.097 | 0.681 | 7" | 1.837 |

1" | 1.125 | 0.125 | 0.862 | 19" | 3.025 |

1-1/4" | 1.375 | 0.160 | 1.054 | 11" | 4.53 |

1-1/2" | 1.625 | 0.190 | 1.244 | 13" | 6.32 |

2" | 2.125 | 0.236 | 1.653 | 17" | 11.15 |

Radiant Heating

In heating applications we need to make sure we deliver sufficient heat at an acceptable temperature for the load demand. All heat transfer happens at the surface of the tubing, so larger tubing should give us more heat transfer, right? Well, if we need to consider tubing spacing in a radiant floor heating installation; the Radiant Professionals Alliance (RPA) recommends a minimum bend radius at 8 times the ID of the tubing. So 1/2 in tubing gets .5 X 8 = 4 in bend radius or a minimum spacing of 8 in on center (without "tear dropping" the returns), 5/8 in tubing gets .625 X 8 = 5 in bend radius or 10 in. tubing spacing. http://www.radiantprofessionalsalliance.org

If we install our tubing on minimum spacing we will have 20% less 5/8 in. tubing installed than 1/2 in. tubing. But if we look at the surface area of tubing, 5/8 in tubing only has 10% more surface area than 1/2 in. tubing ( .75 X Π = 2.355 in. / .625 X Π = 2.12 ). So you would be at a NET loss of surface area or heat transfer when using a larger diameter pipe when installing at minimum tubing spacings in a radiant floor install.

Also the heat carrying capacity of water is so high that 3/8 in diameter tubing is more than sufficient for most radiant floor heating applications. (But let a qualified professional do the math for you just to make sure. )

Free Estimates

Domestic Hot Water Distribution

If are choosing a tubing for domestic hot water distribution to a shower, faucet or other fixture, you need to consider the time it takes to get cold water out of the line. A 5/8 in supply line to a sink will have 50% more water than the 1/2 in supply line and a 3/4 in. supply line will have 100% more water in the line. So you will experience a 50% to 100% increase in time or wasted water when turning on a faucet before the hot water reaches the fixture when you increase the tubing diameter. FYI - 3/8 in. tubing carries half as much water as 1/2 in. and will respond twice as fast.

2) 180°F is the maximum fluid temperature for PEX tubing.

ASTM specifications F877 for PEX tubing is a Pressure @ Temperature rating. As the temperature increases the max operating pressure drops.

Most PEX tubing will be rated for:

- 160 psi at 73°F

- 100 psi at 180°F

- 80 psi at 200°F

(Pipe steam through PEX at your own risk. )

1) All PEX tubing is the same.

All PEX tubing needs to conform to the ASTM F876 & F877 for

temperature, pressure and quality as well as the SDR-9 dimension

standards. Most PEX tubing exceed those standards. But that is where

they stop their similarities.

All PEX tubing needs to conform to the ASTM F876 & F877 for

temperature, pressure and quality as well as the SDR-9 dimension

standards. Most PEX tubing exceed those standards. But that is where

they stop their similarities.

When evaluating tubing you should look at:

- Warranty - Where was the tubing manufactured and what company is covering the warranty and is YOUR installation covered.

This is one of the biggest factors in choosing a tubing product. Will the warranty cover property damage due to a failure, probably not. But will it cover parts and labor if failure is due to a manufacturing defect? Some do, some only give you more tubing.

Is YOUR installation covered due to manufacturers defect? Some manufacturer warranties cover the product, some will only cover your claim if it was installed by a licensed trained installer. Check the fine print before you buy.

You might say that you never have a warranty claim and you might never have one. But you can bet that a reputable manufacturer that writes a more open warranty will do more to maintain the quality in their product.

- Durability vs Flexibility - Does your installation method call for more durable tubing or more flexible tubing?

When asking a crew of pipe fitters to drag your PEX pipe across some rebar and then let the masons bury it in concrete while using shovels and rakes and implements of destruction, you might want to put your hands on the most durable tubing you can get. High burst pressure is a good indicator of a durable tubing. It is also less flexible and more rigid than some other brands in in the same price point.

But if you are stapling tubing down to a subfloor to be encased in light weight concrete, then you might want the most flexible tubing you can find. This will allow you to put the tubing on tighter centers (without tear dropping the returns) to give a more uniform floor temperature. It will also make for easier routing around built-ins like cabinets and doorways.

- Price - You get what you pay for.

"Cheap" as two meanings and you may just find you will be using that warranty if you choose incorrectly. Consider your application; if I was installing tubing in my 600 sqft shop/garage I might choose a different tubing than my 2000 sqft house. I would definitely use the best tubing I could afford if my business and reputation was at risk. The last thing a contractor needs is a home owner or GC questioning his choice of PEX. Even though they won't see the product after it is installed, they may see the boxes before the dumpster is hauled away.

- Add-Ons - More options than before.

PEX used to be PEX. Then it became Water PEX for domestic water distribution and O² Barrier PEX for heating systems. Now manufactures give us a few more options to help.

- Oxygen Barrier to protect corrosion susceptible components in a heating system

- Low Friction coatings for easier installation and low noise performance

- Various Colors like Red, White, Blue and Orange

- Pre-Insulated PEX for under ground installations

- PEX-AL-PEX with an aluminum core for higher performance and virtually no expansion.

Conclusion

With all these options you can easily make the wrong choice of tubing for your next project. Consult a design professional and he can guide you to getting the right product for the job. Because your PEX tubing can be literally set in stone. Free Estimates